When it comes to lifting heavy loads, the design of an overhead crane plays a critical role in determining its efficiency, safety, and longevity. Among the various designs available, the double girder overhead crane stands out as the ideal choice for applications requiring high load capacities, such as 100-ton lifting. This article will delve into the reasons why the double girder design is best suited for 100 ton overhead crane, exploring its advantages in terms of performance, durability, safety, and adaptability.

Understanding Overhead Crane Design

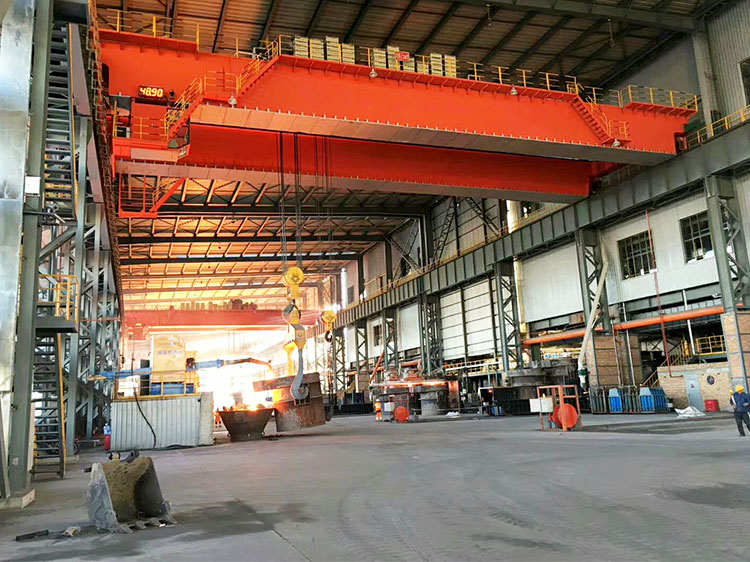

Overhead cranes are essential in industries like manufacturing, steel mills, construction, and logistics, where heavy lifting and precise material handling are crucial. The design of an overhead crane typically consists of several key components: the hoist mechanism, the trolley, the bridge (which spans the area), and the girders.

The primary difference between single girder and double girder designs lies in the structure of the crane’s bridge.

- Single Girder Cranes: These cranes use a single beam or girder to support the hoist and trolley. While they are suitable for light to medium-duty applications (typically up to 20-30 tons), they are not well-suited for very heavy lifting, such as 100 tons.

- Double Girder Cranes: As the name suggests, these cranes employ two parallel girders, providing superior structural strength and stability. This design is ideal for lifting heavy loads, making it the preferred choice for 100-ton capacity overhead cranes.

Advantages of Double Girder Design for 100-Ton Overhead Cranes

- Superior Load-Bearing Capacity

The primary advantage of the double girder design is its ability to bear significantly higher loads compared to a single girder system. A 100-ton overhead crane requires a robust structure that can handle heavy, dynamic forces without compromising stability. The two girders in a double girder bridge crane distribute the load evenly, reducing the stress placed on any single component. This ensures that the crane can safely lift heavy objects without risk of failure, even under the most demanding conditions.

For example, in steel mills or large manufacturing plants, where heavy steel plates or machinery parts need to be transported, the double girder design offers the necessary strength to handle the weight. This makes it ideal for industries where the loads frequently exceed 50 tons and can go up to 100 tons.

- Increased Vertical Lifting Height

In a double girder crane, the hoist is suspended between the two girders, providing more vertical lifting height. This is crucial for handling large or bulky loads that need additional clearance. The increased lifting height allows for more flexible operations, making it easier to stack or position oversized loads precisely.

For 100-ton overhead cranes, especially in environments such as shipyards or construction sites, lifting height is a key consideration. Having more vertical space allows operators to lift loads over tall structures or clear obstacles in their path, improving efficiency and versatility in their operations.

- Better Stability and Safety

Safety is paramount when dealing with heavy-duty cranes, especially when lifting loads as heavy as 100 tons. The double girder design enhances the overall stability of the crane, reducing sway and minimizing the risk of tipping. The two girders provide a wider and more stable base, which distributes the load more evenly and ensures that the crane remains steady during operation.

Additionally, double girder cranes are less likely to experience twisting or bending of the bridge when lifting heavy loads. This is crucial when dealing with 100-ton capacity cranes, as the forces at play can be quite substantial. With the added stability, the crane operates more safely, reducing the risk of accidents, structural failures, or damage to the equipment.

- Greater Durability and Longevity

Another key advantage of double girder cranes is their superior durability. The additional structural support provided by the two girders helps prevent excessive wear and tear on the crane’s components. This is particularly important in high-duty cycles, where the crane is frequently used for heavy lifting.

For industries that rely on 100-ton cranes, such as power plants, mining, or large manufacturing facilities, durability is a critical factor. Double girder cranes are built to withstand the stresses associated with frequent use and heavy loads, ensuring a longer lifespan. Properly maintained double girder eot cranes can provide decades of service, reducing downtime and maintenance costs for businesses.

- Enhanced Load Distribution and Hoist Efficiency

In a double girder crane, the hoist is generally positioned on top of the girders, allowing for more efficient use of space. This design also allows for the use of larger, more powerful hoisting mechanisms capable of lifting heavier loads more efficiently. The improved load distribution reduces the strain on the hoist, allowing it to operate smoothly even under the heaviest loads.

This is a particularly valuable feature for 100-ton overhead cranes, as efficient load distribution directly affects the speed and effectiveness of lifting operations. The increased mechanical efficiency means that the crane can handle more demanding tasks without the need for frequent repairs or downtime.

- Versatility in Design and Customization

The double girder design is highly adaptable and can be customized to meet the specific needs of a particular application. For instance, the span of the crane, the lifting height, and the type of hoist can all be tailored to suit the requirements of a facility. Whether it’s for a shipyard, an assembly line, or a steel mill, a double girder crane can be designed to fit the exact needs of the operation.

For 100-ton overhead cranes, this flexibility allows businesses to invest in equipment that is optimized for their unique operational requirements. Customizing the bridge crane for sale ensures that it operates at peak efficiency, leading to improved productivity and a better return on investment.

- More Efficient Use of Space

The design of double girder cranes allows for more efficient use of available space, which is crucial in environments with limited overhead clearance. With the hoist positioned between the two girders, the crane can operate in narrower spaces while still achieving a high lifting capacity. This makes double girder cranes an ideal solution for industries that require both heavy lifting and space efficiency.

In facilities such as warehouses, factories, or ports, the ability to maximize space without compromising lifting capacity is a significant advantage. For a 100-ton crane, this space efficiency can result in improved workflows, reduced congestion, and a more streamlined operation.

Conclusion

The double girder design is undoubtedly the ideal choice for 100-ton overhead cranes due to its superior load-bearing capacity, increased vertical lifting height, enhanced stability, durability, and customization options. For industries that require heavy lifting—such as steel manufacturing, power plants, and large-scale construction—this crane design offers the strength and versatility needed to handle the most demanding tasks safely and efficiently.

By investing in a double girder 100-ton overhead crane, businesses can improve productivity, reduce maintenance costs, and ensure safe and reliable operations for years to come. The structural integrity and performance advantages of the double girder design make it a clear winner for heavy-duty lifting applications, ensuring that operations run smoothly, even when dealing with the most challenging loads.