The construction and logistics industries have witnessed a remarkable evolution in materials handling and lifting technology over the years. Rail-mounted gantry cranes (RMGs) stand as a testament to this transformation, offering a range of benefits that have made them indispensable in various applications. In this article, we will delve into the numerous advantages of using rail-mounted gantry cranes, exploring how they optimize efficiency, precision, and safety across different industries.

Understanding Rail-Mounted Gantry Cranes

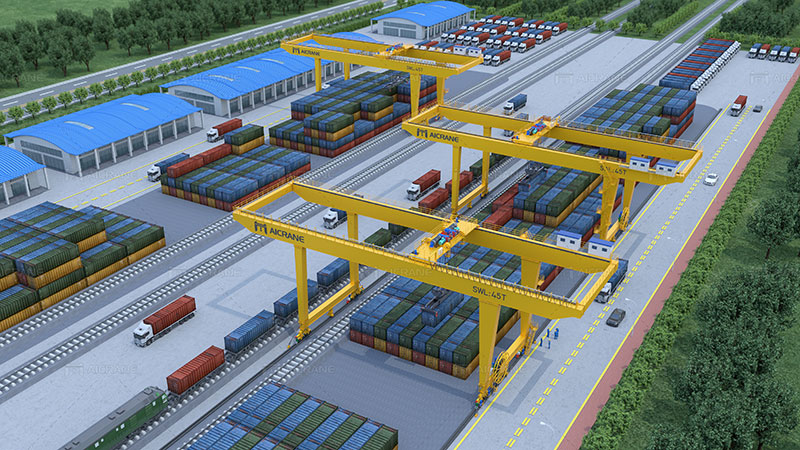

Rail-mounted gantry cranes are specialized lifting machines that are designed to operate on tracks or rails. They are commonly found in shipping ports, intermodal terminals, manufacturing facilities, and even some construction sites. The key feature that sets RMG cranes apart from other cranes is their ability to move along a fixed path, providing exceptional stability and precision during lifting operations.

Key Features of RMGs

Rail-Based Movement: RMGs operate on a network of rails or tracks, allowing them to move horizontally with unparalleled precision. This fixed path ensures that loads can be positioned with accuracy, making them ideal for applications where precision is critical.

Vertical Lifting: RMGs are equipped with a hoisting mechanism that enables them to lift heavy loads to significant heights. This makes them suitable for stacking containers in ports, handling heavy machinery components in manufacturing, and more.

Span and Height Adjustability: Many RMGs are designed with adjustable spans and heights, providing versatility to handle different types of loads and adapt to various operational requirements.

Remote Operation: Modern RMGs often come with remote control systems, allowing operators to manage the crane from a safe distance. This feature enhances safety and control during lifting operations.

Benefits of Using RMGs

Precision Handling: One of the primary benefits of using RMGs is their precision handling capabilities. These container handling gantry cranes are designed to move along a predetermined path with accuracy, making them ideal for applications that require careful positioning of loads. In ports, for example, RMGs can stack containers with minimal clearance, maximizing storage space.

Efficiency and Productivity: RMGs are known for their high lifting capacities and speed. In container terminals, they can move and stack containers quickly, significantly increasing the efficiency of cargo handling operations. In manufacturing, RMGs can lift and transport heavy components swiftly, reducing downtime and improving overall productivity.

Reduced Labor Costs: The automation and precision offered by RMGs reduce the need for extensive manual labor in materials handling operations. This results in cost savings in terms of labor expenses and minimizes the risk of accidents associated with manual handling.

Safety: Safety is a paramount concern in industries that rely on heavy lifting equipment. RMGs enhance safety by minimizing human involvement in the lifting process. Remote control systems further reduce the risk to operators, ensuring that they are at a safe distance from potentially hazardous loads.

Versatility: RMGs are adaptable to various applications and industries. They can be customized with different spreader attachments to handle containers, steel coils, machinery, and more. Their adjustable span and height features make them versatile enough to accommodate diverse operational needs.

Space Optimization: In facilities with limited space, RMGs shine as they can operate efficiently in confined areas. Their ability to stack containers and materials with precision means that vertical space is maximized, allowing for higher storage capacity without the need for expansion.

Applications of RMGs

Port and Terminal Operations: RMGs are a staple in container terminals, where they are responsible for stacking and organizing shipping containers. Their precision and speed are essential for maximizing the use of space and streamlining cargo handling operations.

Manufacturing: RMGs are employed in manufacturing facilities to transport heavy equipment components, machinery parts, and raw materials. Their ability to lift heavy loads with precision ensures the safe and efficient assembly of various products.

Construction: Some construction sites utilize RMGs for handling heavy construction materials such as precast concrete elements and steel beams. These cranes are particularly useful in large-scale projects where precision is vital.

Logistics and Warehousing: In logistics and warehousing facilities, RMGs are used to move and stack pallets, containers, and other goods. Their precision handling and space-saving capabilities are highly beneficial in such environments.

Challenges and Considerations

While rail-mounted gantry cranes offer a multitude of benefits, it’s essential to consider certain challenges and factors when implementing them:

Infrastructure Investment: Installing the rails and necessary infrastructure for RMGs can be a significant upfront cost. However, this investment often pays off in terms of long-term efficiency gains.

Maintenance: Regular maintenance is crucial to ensure the smooth operation of RMGs. Downtime due to maintenance can impact productivity, so a well-planned maintenance schedule is essential.

Operator Training: Proper training is vital for RMG operators to ensure safe and efficient crane operation. Operators must be skilled in maneuvering the gantry crane along the rails and handling loads with precision.

Conclusion

Rail-mounted gantry cranes have become integral components in industries that demand precision, efficiency, and safety in materials handling and lifting operations. Their ability to move along fixed paths, lift heavy loads to significant heights, and operate with precision has made them invaluable in ports, manufacturing, construction, and logistics. While the initial investment in RMG infrastructure and technology can be substantial, the long-term benefits in terms of productivity, safety, and space optimization make them a wise choice for businesses looking to streamline their operations and stay competitive in today’s fast-paced industrial landscape.