The world of maritime operations is characterized by constant innovation and a relentless pursuit of efficiency, safety, and sustainability. Within this dynamic environment, deck winches have long played a crucial role in anchoring, mooring, and cargo handling on vessels of all sizes. While traditional winches relied on hydraulic or manual power, a new wave of technology is reshaping the seascape: electric deck winches. In this article, we’ll embark on a journey to explore how electric deck winches are setting a course for the future of marine operations, redefining industry standards, and contributing to safer and more sustainable shipping.

To appreciate the significance of electric deck winches, it’s essential to understand their evolutionary journey. Historically, manual labor was the backbone of deck operations. Crew members would exert significant physical effort to manipulate ropes and cables for anchoring and mooring. The transition to hydraulic winches brought automation and increased power, but hydraulic systems posed challenges such as maintenance, fluid leaks, and complex hydraulic networks.

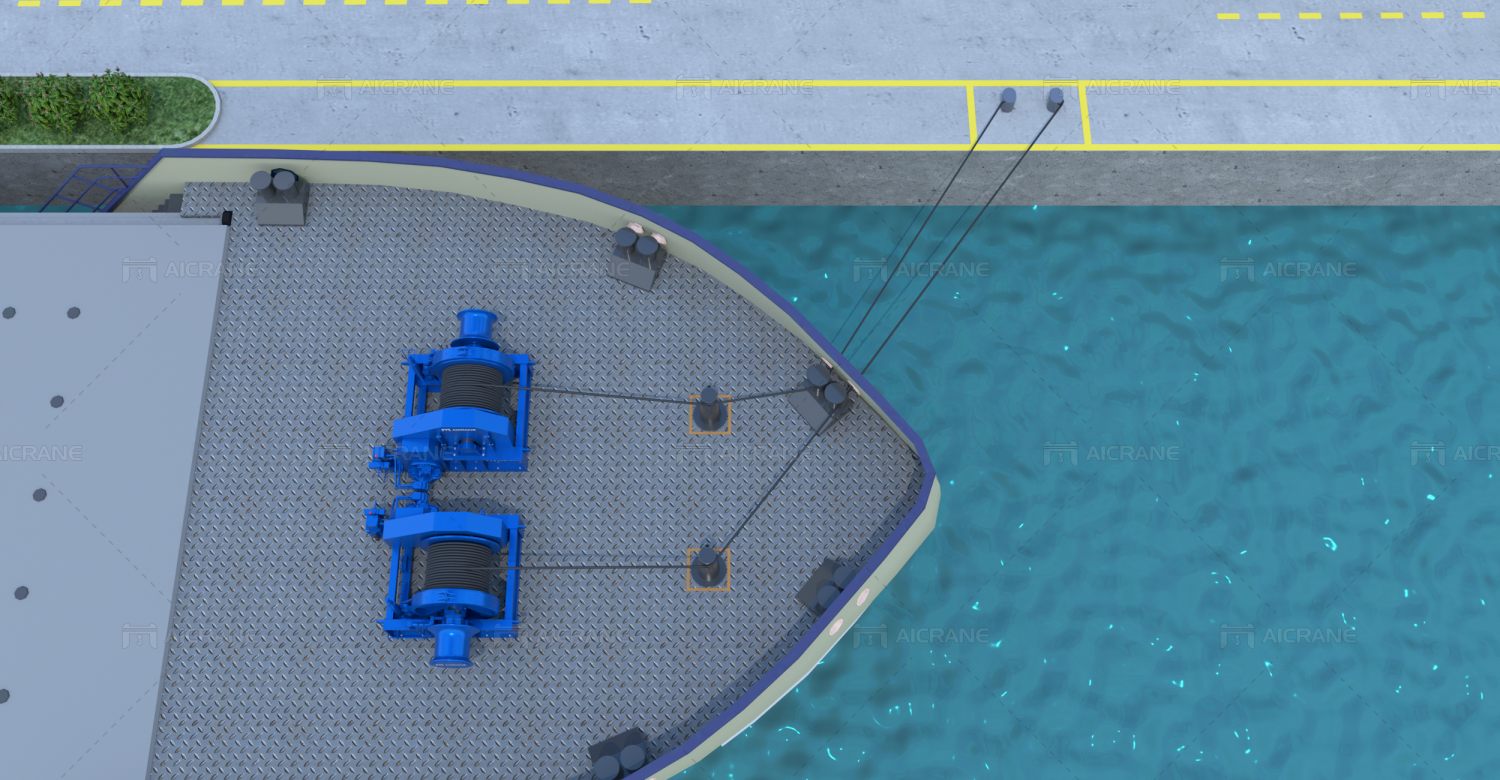

Electric deck winches represent the latest leap forward. They offer a compelling blend of precision, power, and eco-friendliness, making them a game-changing addition to maritime operations.

Harnessing Technology for Precision Control

Electric deck winches are characterized by their precise control, setting them apart from their hydraulic counterparts. Hydraulic systems can be sensitive to variations in hydraulic fluid temperature and viscosity, affecting the consistency of control. Electric winches, on the other hand, provide precise and consistent control over line tension and speed. This level of precision is critical when it comes to anchoring, mooring, and cargo handling, where accurate adjustments are essential for safety and efficiency.

Reduced Maintenance for Greater Reliability

Maintenance is a constant consideration in maritime operations. Hydraulic winches require regular upkeep to prevent issues like fluid leaks, pump failures, and hose ruptures. Electric deck winches, in contrast, have fewer moving parts and don’t rely on hydraulic fluids. This results in reduced maintenance requirements, lower downtime, and greater overall reliability, ensuring that vessels spend more time at sea and less time in dry dock.

Embracing Energy Efficiency

Sustainability is a growing concern in the maritime industry. Electric deck winches align with this concern through their energy-efficient design. They can be equipped with variable frequency drives (VFDs) that optimize power consumption. Unlike hydraulic systems that operate at a fixed speed, regardless of the load, electric winches adjust their power usage according to the load’s demands. This translates to energy savings and reduced operating costs, while also reducing the vessel’s environmental impact.

A Quiet Revolution: Silent and Smooth Operations

Noise pollution is a concern for both crew members and passengers on board. Hydraulic winches can generate noisy vibrations and fluid-related noises that can disrupt the peace on a vessel. Electric deck winches operate more quietly, creating a more pleasant and peaceful environment for everyone on board. This improvement in onboard comfort is an often-overlooked benefit of electric winches.

Enhanced Safety

Safety at sea is paramount, and electric deck winches contribute to a safer maritime environment. Their precise control minimizes the risk of accidents and equipment failures. Furthermore, the absence of hydraulic fluid eliminates the potential hazards associated with leaks and spills, making the vessel’s deck safer for crew members and reducing the risk of environmental damage.

Remote Monitoring and Automation

We live in an era where remote monitoring and automation are transforming industries, and maritime operations are no exception. Electric deck winches can be seamlessly integrated into a vessel’s automation system, allowing for remote monitoring and control. Operators can adjust marine winch settings and monitor line tension from a centralized control station, enhancing efficiency and safety during deck operations.

Versatility and Adaptability

Electric deck winches are incredibly versatile and can be customized to meet the specific needs of different vessels and deck operations. Whether it’s a small recreational boat or a large commercial vessel, electric winches can be configured to handle various loads and line sizes. This adaptability makes them a valuable addition to any vessel’s equipment arsenal.

The Future of Marine Operations

As we sail into the future, electric deck winches are set to redefine marine operations in several key ways:

- Sustainability: The maritime industry is embracing sustainability, and electric deck winches play a vital role in reducing a vessel’s environmental footprint.

- Efficiency: Precise control and reduced maintenance contribute to more efficient deck operations, minimizing downtime and enhancing productivity.

- Safety: Enhanced safety features and the elimination of hydraulic fluid hazards create a safer working environment.

- Automation: Integration with automation systems streamlines operations, reduces the workload on crew members, and enhances safety.

- Comfort: Quieter and smoother operations improve the onboard experience for passengers and crew.

In conclusion, electric deck winches are at the forefront of innovation in maritime operations. Their precision control, reduced maintenance, energy efficiency, safety enhancements, remote monitoring capabilities, and quiet operation make them a compelling choice for vessel operators. As the maritime industry continues to evolve, electric deck winches are setting the course for a future where safety, sustainability, and efficiency are the guiding stars of marine operations, ensuring that vessels navigate the seas with precision and care. For detailed introduction of winch solutions, just open this website https://www.aicraneglobal.com/.